Since this is a new blog, I’ve been watching the traffic – mostly in the laughably vain concern that I might begin to approach my throughput limitation (hey, it’s my fantasy, alright) – and this morning discovered a rather interesting visitor had stopped in.

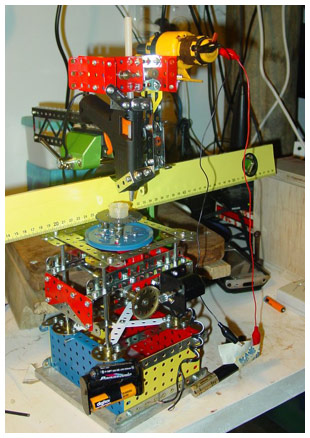

Now before I continue, I should preface this by saying I first read a slew of emails, all RepRap related. Included in one such group email was the confirmation that ABS cylindrical stocks are available and have melt points (~110 C) that make it possible to use this material in that experimental, 4-day-in-the-making, Vik Olliver Meccano effort about which I posted earlier. Having been in the manufacturing side of plastics for years, I can assure you ABS is highly regarded (too often I’ve had to make due with lesser plastics like SAN).

Hence my amusement at a mention by none other than Bruce Sterling on his Wired blog. And while I have nothing to do with the item in question, I do now perhaps have a better understanding of Mr. Sterling – even though I understand the post is intended to poke some fun. Well. Kinda. See, it took four years studying ID before I began to shed my aerospace engineering “blinders” (hey, I got through orbital mechanics mathematics and their painful derivations, but it didn’t make me inventive), and he’s only been at ACCD a few months, I believe. Furthermore, if I recall correctly, he won’t be there much longer. A shame. Hanging around a bunch of students who aren’t polarized into a way of thinking can be liberating… in ways that hanging around experts isn’t. I recall one student in 1992 (now a design firm principal, I believe) having the audacity to suggest handheld cellphone-like devices in ten years! That idiot! If only he’d listened to the impossibility of that development from all the senior instructors and engineers.

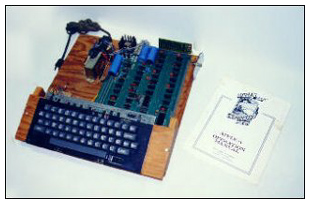

Why respond? Maybe because it was all the comments made by people in the late 70’s. “Whut da hell ya need a ‘puter fer? Ah got me a 350 Chevy.” I recall those kinds of comments. I just didn’t expect Bruce Sterling to be the one to pull them from my memory. What a great reminder of how things are. And how I expect them to continue to be, especially in regards to virtual worlds. I was just having this conversation last night with Jerry… in world….

(note: the above image from 8-Bit Nirvana)